Support rollers

MONTON support rollers have an internal design very similar to that of a needle or cylindrical roller bearing. They are characterized by a thick walled outer ring that enables them to accommodate shock loads while reducing distortion and bending stresses. The outer ring running surface is crowned as standard. However, support rollers with a cylindrical (flat) running surface are available for certain applications.

These pre-greased, ready-to-mount units are suitable for all types of cam drives, tracks and conveyor systems.

Support rollers without flange rings

MONTON Supplies support rollers without separate flange rings in two designs and variants:

• with or without an inner ring

• open or sealed with two integral flanges in the outer ring

MONTON support rollers without flange rings are designed for applications where associated components limit axial movement of the outer ring.

Support rollers with an inner ring have a slightly extended inner ring to enable the ne ces sary axial movement.

MONTON Support rollers without an inner ring are intended for arrangements where the pin or shaft can be hardened and ground.

Support rollers with flange rings

MONTON Support rollers with flange rings are non-separable units and are available in different designs and variants: • with gap-type, labyrinth, polyamide or rubber seals

• with needle or cylindrical rollers

• with one or two rows of rollers

• with a cage-guided or a full complement roller set

NATR design support rollers

NATR design support rollersare fitted with a needle roller and cage assembly. The outer ring is guided axially by pressed-on flange rings. The narrow gap between the flange rings and the outer ring serves as a gap-type seal.

NATV design support rollers

NATV design support rollers are similar to the NATR design, except that they have a full complement of needle rollers. Therefore, NATV support rollers can accommodate heavier radial loads than NATR support rollers. However, because of the kinematic behaviour of the needle rollers, they are not able to operate at

the same high speeds and require more frequent relubrication.

NATR and NATV design support rollers, designation suffix PPA

NATR and NATV design support rollers with the designation suffix PPA have axial sliding rings made of polyamide 66. In the radial direction, the sliding ring forms a narrow labyrinth seal with the outer ring to protect against coarse contaminants. In the axial direction, the sliding ring serves as a contact seal to reliably retain grease in the bearing. This improves the lubrication conditions in the bearing, keeps friction and heat low, and extends grease service life.

NUTR .. A design support rollers

NUTR .. A design support rollers are based on double row full complement cylindrical roller bearings. The outer ring has two integral flanges to axially guide the roller complements. A loose flange ring on both sides of the inner ring provides axial guidance for the outer ring via the roller complements. This enables NUTR .. A design support rollers to accommodate axial loads that occur when operating in a tilted or inclined position and to operate at relatively high speeds.

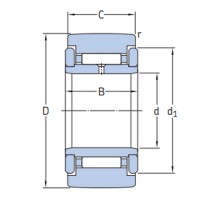

NNTR ...2ZL design support rollers

NNTR ...2ZL design support rollers have a full complement of rollers and can accommodate very heavy radial loads. NNTR ...2ZL design support rollers incorporate a lamellar seal on both sides. These seals are inserted into recesses in the shoulders of the flange rings and the outer ring and provide support to hold the bearing together. Three integral flanges in the outer ring axially guide the two rows of full complement rollers separately to minimize friction in the support roller, thereby reducing the amount of heat generated by the bearing. Two loose flange rings guide the outer ring axially via the roller complements. This enables the support rollers to accommodate the relatively heavy constant axial loads that occur when support rollers operate in an inclined position.

Supplementary designations

The designation suffixes used to identify certain features of MONTON support rollers are explained in

the following:

.2RS Contact seal of acrylonitrile-butadiene rubber (NBR) on both sides of the support roller

.2ZL Support rollers with a lamellar seal on both sides

A NUTR design support rollers with an improved crowned profile of the outer ring running surface

PPA NATR or NATV design support rollers with a polyamide 66 axial sliding and sealing ring on both sides. Improved crowned profile of the outer ring running surface.

TN Injection moulded cage of glass fibre reinforced polyamide 66

X Cylindrical (flat) profile of the outer ring running surface

| auswählen | Anfrage | Bezeichnung | fünfzehn | fünfzehn | Dimensions | Tragzahlen (kN) | Fatigue load limit (kN) | Maximum radial forces (kN) | Limiting speed (r/min) | Masse (kg) | Delivery | Drawing | Original | Package | Brand | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D (mm) | d mm | C mm | B mm | d1 mm | r (Min.) | r1,2min | dynamic C | static Co | Pu | dynamic Fr | static For | ||||||||||||

| NNTR 110x260x115.2ZL | 260 | 110 | 113 | 115 | 143 | 4 | 2.5 | 627 | 930 | 112 | 655 | 950 | 360 | 35.5 | 7-35 days | Available | China | SIngle box | MONTON | ||||

| NNTR 120x290x135.2ZL | 290 | 120 | 133 | 135 | 155 | 4 | 3 | 825 | 1270 | 143 | 900 | 1290 | 320 | 53 | 7-35 days | Available | China | SIngle box | MONTON | ||||

| NNTR 130x310x146.2ZL | 310 | 130 | 144 | 146 | 165 | 5 | 3 | 952 | 1460 | 166 | 1040 | 1500 | 300 | 65 | 7-35 days | Available | China | SIngle box | MONTON | ||||